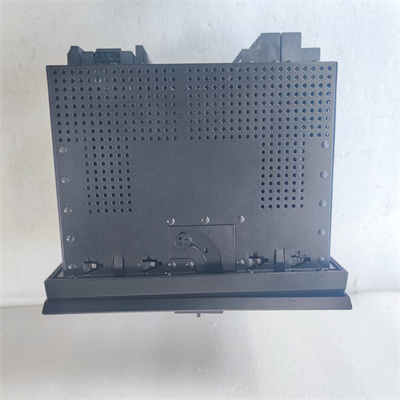

CB801 3BSE042245R1

、

Leveraging the information you provided earlier and what we've learned about ABB's manufacturing processes, here's a possible production description for the ABB CB801 (3BSE042245R1) PROFIBUS DP communication interface:

Understanding the Component:

- CB801: This is likely the main product code for the communication interface.

- 3BSE042245R1: This might be a unique identifier or revision code for this specific variant of the CB801 interface.

Function:

The ABB CB801 is a PROFIBUS DP slave expansion module designed for ABB's Panel 800 series HMI (Human-Machine Interface) or automation controller systems. Here's a breakdown of the functionality:

- PROFIBUS DP: This refers to a widely used industrial communication protocol for connecting field devices like sensors and actuators to programmable controllers.

- Slave Device: The CB801 acts as a slave device on the PROFIBUS DP network, meaning it receives instructions and transmits data to a master controller on the network (typically a Panel 800 HMI or controller).

- Expansion Module: This indicates that the CB801 expands the communication capabilities of the Panel 800 system by enabling it to connect to PROFIBUS DP networks.

Possible Production Process:

Component Sourcing: ABB likely sources various electronic components for the CB801:

- Processor or microcontroller for handling communication protocols and data processing.

- Communication interface transceiver for signal transmission and reception on the PROFIBUS DP network.

- Memory chips for storing configuration data and program logic (if applicable).

- Bus interface circuitry to connect the internal components to the PROFIBUS DP network.

- Power supply circuitry to regulate power for the module.

- Housing components for mechanical protection and mounting within the Panel 800 system.

Printed Circuit Board (PCB) Manufacturing: The PCB design is likely created using computer-aided design (CAD) software. The PCB itself is fabricated according to the design, potentially involving multiple layers with etched circuitry and drilled holes for precise component placement.

PCB Assembly: Automated pick-and-place machines populate the PCBs with the procured electronic components. These components are then securely soldered onto the PCBs using reflow ovens or wave soldering techniques.

Testing and Quality Control: The assembled PCB undergoes rigorous testing to ensure proper functionality:

- Electrical testing to verify proper operation of all components and circuits.

- Communication protocol testing to ensure reliable data exchange on the PROFIBUS DP network.

- Functional testing to confirm the module can communicate with a PROFIBUS DP master device.

Software Installation (Optional): The CB801 might require pre-programmed firmware or configuration specific to ABB's Panel 800 systems during manufacturing.

Packaging and Shipping: Once all tests are passed, the CB801 is labeled according to regulations and securely packaged for shipment to distributors or end users.

Materials and Manufacturing Technology:

- High-quality electronic components to ensure reliable communication and long service life.

- Lead-free soldering processes complying with environmental regulations.

- Surface-mount technology (SMT) for efficient and compact PCB assembly (if applicable).

- Automated testing equipment for consistent quality control.

Finding More Specific Information:

Obtaining extremely detailed information about the specific production process for the ABB CB801 (3BSE042245R1) might be challenging. Here are some suggestions for further exploration:

- ABB Resources:

- Search the ABB website for product manuals or data sheets related to the CB801 communication interface. These resources might provide details about its features, specifications, and configuration procedures for PROFIBUS DP networks.

- ABB might offer technical documents or application notes that discuss their PROFIBUS DP communication modules in more detail.

- Contact ABB Directly: Reach out to ABB's customer support or relevant department. They might be able to share general information about the production process but may not disclose confidential details.

I hope this comprehensive description aids your understanding of the possible production process for the ABB CB801 PROFIBUS DP communication interface!