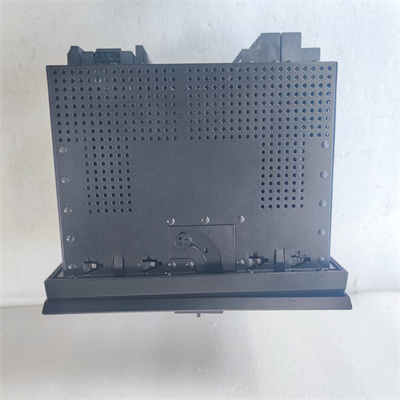

CI854A-eA 3BSE030221

CI854A-eA 3BSE030221 ABB Production Description

While specific details about the production process for CI854A-eA 3BSE030221 (ABB) are not publicly available, here's a possible breakdown based on ABB's reputation for quality and common practices in the industrial automation industry:

Possible Production Stages:

Component Sourcing:

- Industrial-grade electrical components like relays, contactors, or circuit breakers (depending on the specific function of CI854A-eA 3BSE030221).

- Electronic components like timers, counters, or signal conditioners (possible depending on functionality).

- Power supply components for regulating voltage and powering internal circuits.

- Control interface modules for user interaction and system integration (depending on functionality).

- Housing components for enclosing the device and providing protection.

- ABB sources high-quality electrical and electronic components from reliable suppliers that meet their stringent performance and reliability standards. These might include:

Sub-Assembly and Pre-Testing (if applicable):

- Assembly of major electrical components onto a backplane or mounting plate.

- Pre-testing of sub-assemblies to verify functionality and identify potential issues early on (if applicable).

- Depending on the complexity of CI854A-eA 3BSE030221, there might be a sub-assembly stage involving:

Printed Circuit Board (PCB) Manufacturing (if applicable):

- If CI854A-eA 3BSE030221 utilizes a PCB for control logic or communication functions, it would likely be fabricated according to ABB's design. This stage might be outsourced to a specialized PCB manufacturer.

PCB Assembly (if applicable):

- Automated pick-and-place machines for precise component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Additional hand soldering or rework for critical components (possible depending on the design).

- Visual inspection and automated electrical testing to verify component placement and functionality.

- A controlled environment with stringent quality control procedures ensures proper component placement and soldering (if a PCB is used). This may involve:

Final Assembly and Integration:

- Wiring of internal components and connections between sub-assemblies and the PCB (if applicable).

- Installation of user interface components like LEDs, buttons, or a small display (depending on functionality).

- Incorporation of protective features like terminal covers or enclosures for high-voltage connections.

- The sub-assembly (if applicable) and the PCB (if applicable) are integrated into the final housing of CI854A-eA 3BSE030221. This might involve:

Testing and Quality Control:

- Electrical testing to verify circuit functionality, control logic operation, and safety features.

- Performance testing to ensure the device operates as intended under various load conditions (if applicable).

- Compatibility testing to verify communication protocols and interaction with control systems (if applicable).

- Safety testing to ensure the device meets relevant safety standards (e.g., UL, CE) for potential hazards like electrical shock or short circuits.

- Environmental testing to verify the device's performance within its specified operating temperature, humidity, and vibration ranges.

- Rigorous testing is essential for a product like CI854A-eA 3BSE030221, which likely involves:

Final Assembly and Packaging:

- Labeling according to regulations.

- Secure packaging for protection during transportation.

- The final assembly is subjected to a final round of inspection and packaging for shipment. This might involve:

Documentation and Certification:

- User manuals with clear instructions for safe installation, operation, and maintenance.

- Technical specifications detailing functions, control logic (if applicable), and environmental limitations.

- Installation guides for proper integration with control systems and loads (if applicable).

- Certificates of compliance with relevant safety and industry standards.

- ABB likely provides comprehensive documentation for CI854A-eA 3BSE030221. This might include:

Shipping and Distribution:

- Once all requirements are met, CI854A-eA 3BSE030221 is shipped to distributors, industrial automation integrators, or end users for various industrial control applications depending on its specific design (e.g., motor starters, control relays, programmable logic controllers).

Finding More Specific Information:

Obtaining in-depth details about the exact production process for CI854A-eA