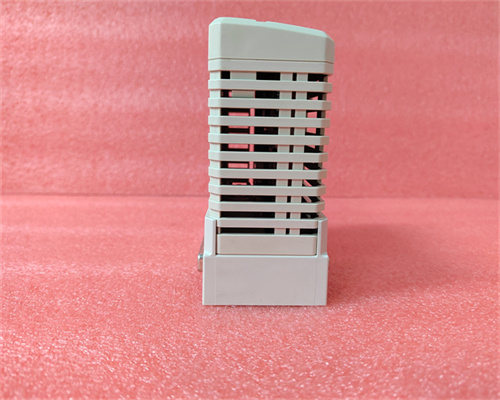

CI858K01 3BSE018135

ABB CI858K01 3BSE018135 Production Description

Based on the trends observed in ABB's communication interface modules and the information available online, here's a possible production process for the CI858K01 3BSE018135:

Function:

The ABB CI858K01 3BSE018135 likely functions as a serial communication interface module used within ABB's industrial automation systems. It acts as a bridge between:

- Control System: This could be a programmable logic controller (PLC) or automation controller from ABB that manages the overall process control logic.

- Serial Devices: These might include sensors, actuators, or other industrial devices that communicate using serial protocols like RS-232 or RS-485. The CI858K01 translates signals from the control system into a format compatible with these serial devices.

Possible Production Process:

Component Sourcing: ABB likely sources various electronic components for the CI858K01:

- Microcontroller or communication processor for handling data processing and protocol conversion between the control system and serial devices.

- Serial communication interface circuitry, including level shifters or isolation transformers (depending on the specific serial protocol) for ensuring reliable communication with serial devices.

- Network interface circuitry for connecting to the control system's backplane or communication bus (specific interface type depends on the ABB control system model).

- Memory chips for storing configuration data and program logic related to serial communication protocols (if applicable).

- Power supply circuitry to regulate power for the module's operation.

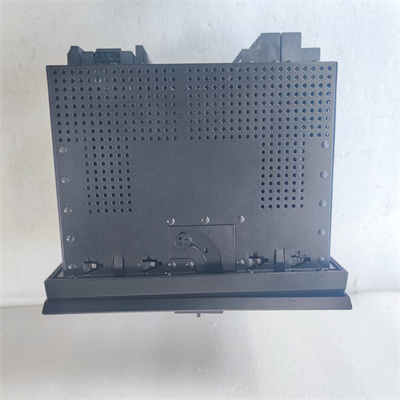

- Housing components for mechanical protection and mounting within a control system cabinet.

Printed Circuit Board (PCB) Manufacturing: The design is likely created using computer-aided design (CAD) software. The PCB itself is fabricated according to the design, potentially involving multiple layers with etched circuitry and drilled holes for precise component placement.

PCB Assembly: Automated pick-and-place machines populate the PCBs with the procured electronic components. These components are then securely soldered onto the PCBs using reflow ovens or wave soldering techniques.

Testing and Quality Control: The assembled PCB undergoes rigorous testing to ensure proper functionality:

- Electrical testing to verify the functionality of the microcontroller, communication interfaces, and power supply.

- Communication protocol testing to confirm accurate data exchange with the control system and serial devices.

- Functional testing to ensure the module can translate signals and operate reliably with the chosen serial protocol(s).

Software Installation (Optional): The CI858K01 might require pre-programmed firmware specific to ABB's control systems for communication protocols and functionalities.

Packaging and Shipping: Once all tests are passed, the CI858K01 3BSE018135 is labeled according to regulations and securely packaged for shipment to distributors or end users.

Materials and Manufacturing Technology:

- High-quality electronic components to ensure reliable communication and long service life in the industrial automation environment.

- Lead-free soldering processes complying with environmental regulations.

- Surface-mount technology (SMT) for efficient and compact PCB assembly (if applicable).

- Automated testing equipment for consistent quality control.

Finding More Specific Information:

Obtaining extremely detailed information about the specific production process for the ABB CI858K01 3BSE018135 might be challenging. Here are some suggestions for further exploration:

- ABB Resources:

- Search the ABB website for product manuals or data sheets related to the CI858K01 communication interface module. These resources might provide details about its features, specifications, supported serial protocols, configuration procedures, and compatibility with ABB control systems.

- ABB might offer application notes or technical documents that discuss ABB's serial communication solutions and the role of serial interface modules within their automation systems.

- Contact ABB Directly: Reach out to ABB's customer support or relevant department. They might be able to share general information about the production process but may not disclose confidential details.

I hope this comprehensive description is helpful!