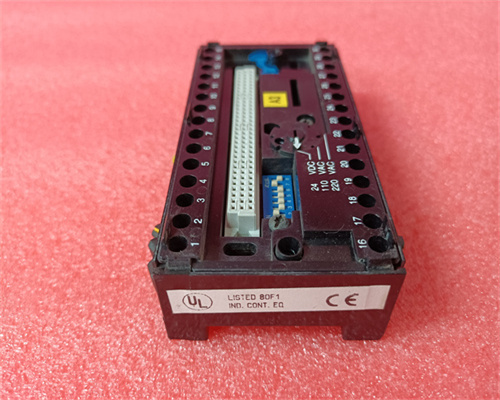

CS31

CI867 3BSE043661R1 ABB Production Description

While specific details about the production process for CI867 3BSE043661R1 (ABB) are not publicly available, here's a possible breakdown based on ABB's reputation for quality and common practices in the industrial automation and power conversion industry:

Possible Production Stages:

Component Sourcing:

- Power electronic components like thyristors, IGBTs (Insulated-Gate Bipolar Transistors), or MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) depending on the specific function of CI867 3BSE043661R1 (e.g., DC/AC inverter, motor drive, soft starter).

- Gate driver circuits to control the power electronic devices efficiently.

- Microcontroller or digital signal processor (DSP) for intelligent control algorithms (likely depending on functionality).

- Passive components like resistors, capacitors, and inductors for signal conditioning, filtering, and power conversion.

- Heat sink components for dissipating heat generated by power electronic devices.

- Control and communication interface modules for user interaction and system integration (depending on functionality).

- ABB sources high-quality electrical and electronic components from reliable suppliers that meet their stringent performance and reliability standards. These might include:

Sub-Assembly and Pre-Testing (if applicable):

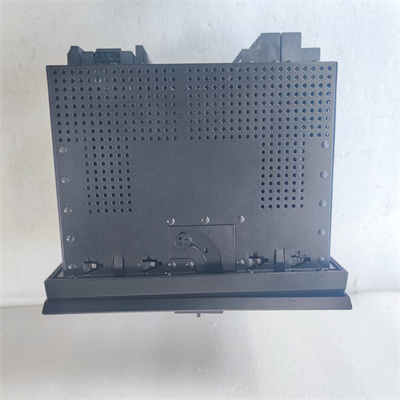

- Assembly of power electronic devices, heat sinks, and driver circuits onto a baseplate.

- Pre-testing of sub-assemblies to verify functionality and identify potential issues early on.

- Depending on the complexity of CI867 3BSE043661R1, there might be a sub-assembly stage involving:

Printed Circuit Board (PCB) Manufacturing (if applicable):

- If CI867 3BSE043661R1 utilizes a PCB for control logic, communication functions, or signal processing, it would likely be fabricated according to ABB's design. This stage might be outsourced to a specialized PCB manufacturer.

PCB Assembly (if applicable):

- Automated pick-and-place machines for precise component placement.

- Reflow ovens or wave soldering techniques for secure connections, likely with a focus on high-current carrying capacity.

- Additional hand soldering or rework for critical components (possible depending on the design).

- Visual inspection and automated electrical testing to verify component placement, functionality, and power handling capabilities.

- A controlled environment with stringent quality control procedures ensures proper component placement and soldering (if a PCB is used). This may involve:

Final Assembly and Integration:

- Installation of user interface components like LEDs or displays for user interaction (if applicable).

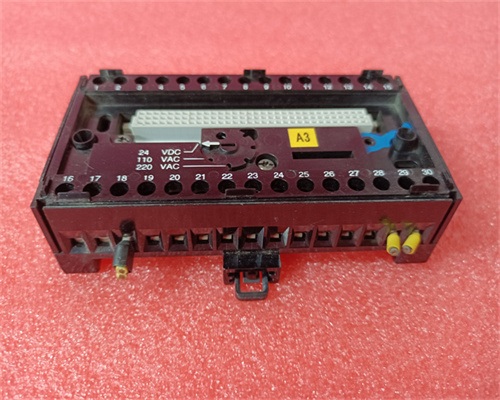

- Connecting power terminals and control connectors for AC or DC input and output depending on the function.

- Installing additional components like busbars or capacitors for high-power handling (if applicable).

- Incorporating protective features like covers for high-voltage connections and cooling fans for thermal management.

- The sub-assembly (if applicable) and the PCB (if applicable) are integrated into the final housing of CI867 3BSE043661R1. This might involve:

Testing and Quality Control:

- Electrical testing to verify power handling capabilities, control functionality, and safety features.

- Performance testing to ensure the device operates as intended under various load conditions (e.g., efficiency testing for inverters).

- Functional testing to verify communication protocols and interaction with control systems (if applicable).

- Safety testing to ensure the device meets relevant safety standards (e.g., UL, CE) for potential hazards like overcurrent, overvoltage, and short circuits.

- Environmental testing to verify the device's performance within its specified operating temperature, humidity, and vibration ranges.

- Rigorous testing is essential for a product like CI867 3BSE043661R1, which likely involves:

Final Assembly and Packaging:

- Labeling according to regulations.

- Secure packaging for protection during transportation.

- The final assembly is subjected to a final round of inspection and packaging for shipment. This might involve:

Documentation and Certification:

- User manuals with clear instructions for safe installation, operation, and maintenance.

- Technical specifications detailing power ratings, efficiency (if applicable), communication protocols (if applicable), and environmental limitations.

- Installation guides for proper integration with power sources, motors, or loads (depending on

- ABB likely provides comprehensive documentation for CI867 3BSE043661R1. This might include: