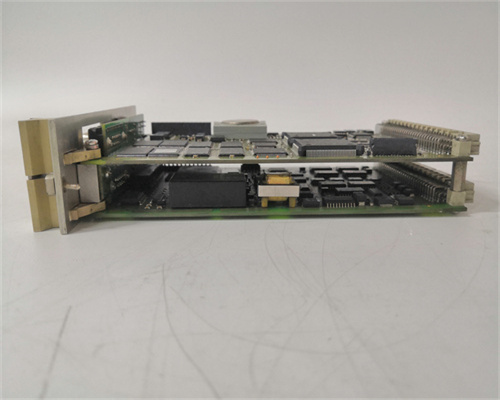

F8650X 984865065

F8650X 984865065 HIMA Production Description

The F8650X 984865065 is a safety-related CPU module manufactured by HIMA, a leading supplier of industrial control products known for their focus on safety and reliability. Here's a possible breakdown of its production process:

Components:

- High-quality electronic components to ensure reliable operation in demanding industrial environments:

- Microprocessor or microcontroller for core processing and control functions.

- Memory chips for storing program code, user data, and operating system.

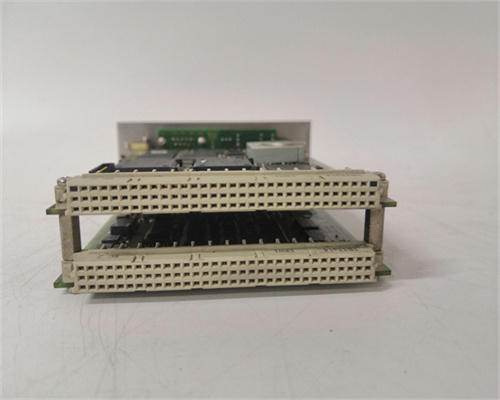

- Input/output (I/O) interface circuits for communication with sensors, actuators, and other devices.

- Power supply circuitry for regulating and distributing power throughout the module.

- Back-up battery (likely) to maintain critical functions in case of power failure (as mentioned in some product descriptions).

Production Stages:

Component Sourcing:

- HIMA sources electronic components from reliable suppliers that meet their stringent quality standards. These components are likely qualified for harsh industrial environments and extended lifespans.

PCB (Printed Circuit Board) Manufacturing:

- The PCB is likely fabricated according to HIMA's design specifications by a specialized PCB manufacturer. This involves high-precision processes to ensure reliable electrical connections and signal integrity, especially crucial for safety-related applications.

PCB Assembly:

- Automated pick-and-place machines for accurate component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Additional hand soldering or rework for critical components.

- Automated and visual inspection to verify component placement, correct soldering, and absence of defects.

- In a controlled environment with stringent quality control procedures, the electronic components are precisely placed and soldered onto the PCB. This might involve:

Programming and Testing:

- Functional testing to verify the CPU's processing capabilities and communication protocols.

- Performance testing to assess processing speed, memory access times, and real-time response under various load conditions.

- Safety testing according to relevant safety standards (e.g., IEC 61508) to confirm the module's ability to operate reliably and safely in case of faults or failures. This might involve testing for potential electrical hazards, overcurrent conditions, and proper system response to critical events.

- Environmental testing to verify the module's performance within its specified operating temperature, humidity, and vibration ranges, simulating real-world industrial environments.

- The PCB undergoes programming to define its control logic and communication protocols. This ensures proper operation within a safety-critical system.

- Rigorous testing is performed to ensure proper functionality, including:

Final Assembly and Packaging:

- The completed PCB is placed in its designated housing, and any additional components like connectors and the backup battery (if applicable) are installed.

- The final assembly undergoes a final round of inspection for functionality, safety compliance, and cosmetic defects.

- Secure packaging is used to protect the module during transportation and storage.

Documentation:

- User manuals with clear instructions for safe installation, configuration, and operation, emphasizing safety considerations in safety-critical applications.

- Technical specifications detailing the module's processing power, memory capacity, communication protocols, safety ratings, and environmental limitations.

- HIMA likely provides comprehensive documentation for the F8650X 984865065, including:

Additional Notes:

- The specific production process might vary depending on the exact model and revision of the F8650X CPU module.

- HIMA likely has a robust quality management system in place to ensure the highest levels of quality and reliability for their safety-critical products.