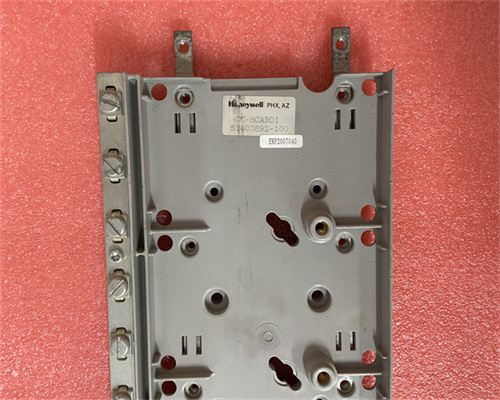

CC-MCAR01

Honeywell CC-MCAR01 Production Description

Based on the information available online and trends observed in Honeywell's control system components, here's a possible production process for the CC-MCAR01:

Function:

The Honeywell CC-MCAR01 is a carrier channel assembly used within the Honeywell Experion process control system. It likely provides +24VDC power to other modules mounted within the same cabinet. Here's a breakdown of its potential functionalities:

- Power Distribution: The CC-MCAR01 distributes +24VDC power from a central source to compatible modules within the control system cabinet. This ensures a stable and reliable power supply for these modules.

- Grounding: It might also include a dedicated bus bar for grounding the shields of field wiring connected to these modules, reducing electrical noise and improving signal integrity.

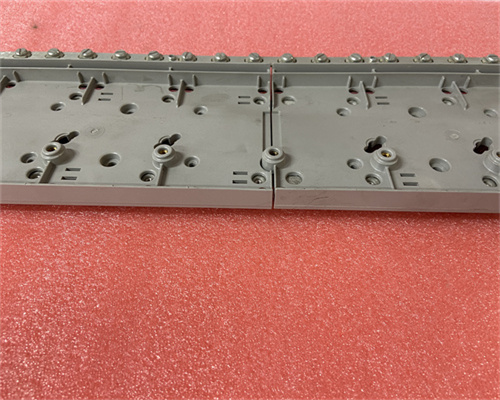

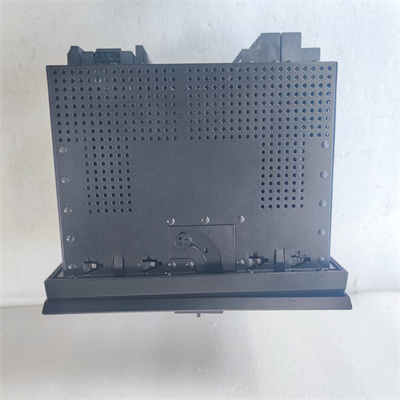

- Physical Support: The CC-MCAR01 might serve as a mounting bracket for other modules, promoting organized and space-efficient cabinet layout.

Possible Production Process:

Component Sourcing: Honeywell likely sources various parts from their suppliers:

- Sheet metal for the housing and internal components of the carrier channel.

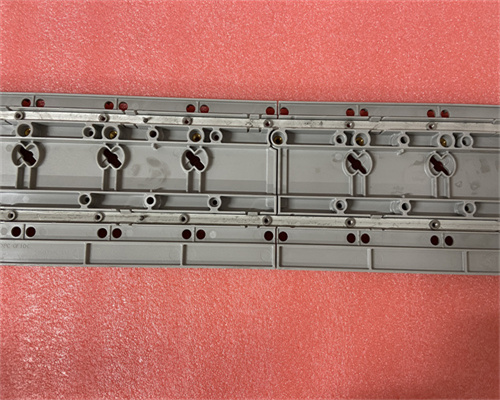

- Bus bars for +24VDC power distribution and grounding.

- Electrical connectors for power input and output connections.

- Mounting hardware for attaching the CC-MCAR01 to the cabinet and potentially for mounting other modules onto it (if applicable).

Metal Fabrication: The sheet metal components are likely shaped and formed using processes like punching, bending, and shearing. These processes create the basic structure of the carrier channel.

Bus Bar Assembly: The +24VDC and grounding bus bars are cut to length and prepared for connection. This might involve drilling holes or adding terminals for secure connections.

Assembly: The various components are assembled together. This could involve:

- Welding or riveting the sheet metal parts to form the housing.

- Installing the bus bars within the housing.

- Attaching electrical connectors and mounting hardware.

Quality Control: The assembled CC-MCAR01 undergoes inspections to ensure:

- Proper fit and finish of the metal components.

- Secure connections of the bus bars and electrical components.

- Functionality of the power distribution and grounding paths.

Packaging and Shipping: Once all tests are passed, the CC-MCAR01 is labeled according to regulations and securely packaged for shipment to distributors or end users.

Materials and Manufacturing Technology:

- High-quality sheet metal for durability and structural integrity.

- Tin-plated or nickel-plated copper bus bars for efficient current conduction and corrosion resistance.

- Industrial-grade electrical connectors for reliable power connections.

- Automated or manual assembly processes depending on production volume.

Finding More Specific Information:

Obtaining extremely detailed information about the specific production process for the Honeywell CC-MCAR01 might be challenging. Here are some suggestions for further exploration:

- Honeywell Resources:

- Search the Honeywell website for product manuals or data sheets related to the CC-MCAR01 carrier channel assembly. These resources might provide details about its specifications, installation instructions, and compatible modules within the Experion system.

- Honeywell might offer technical documentation or application notes that discuss the Experion control system architecture and the role of carrier channel assemblies.

- Contact Honeywell Directly: Reach out to Honeywell's customer support or relevant department. They might be able to share general information about the production process but may not disclose confidential details.

I hope this comprehensive description aids your understanding of the possible production process for the Honeywell CC-MCAR01!