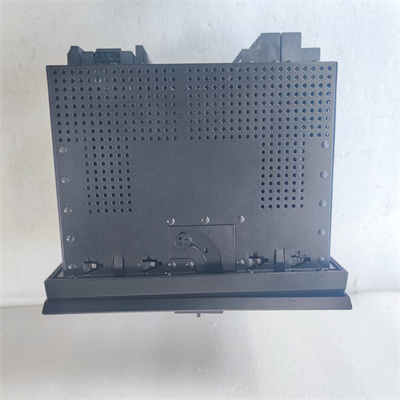

CC-IP0101

CC-IP0101 Honeywell Production Description

The CC-IP0101 is a Profibus DP gateway module by Honeywell. While specific details about its production process might be proprietary, here's a possible breakdown based on industry practices for industrial communication modules:

Possible Production Stages:

Component Sourcing:

- Microcontroller or programmable logic device (PLD) for processing communication protocols and data exchange.

- Communication interface chips for Profibus DP protocol and potentially Ethernet connectivity.

- Memory chips (RAM and flash) to store program code and configuration data.

- Power supply components for regulating power to internal circuits.

- Bus transceivers for reliable signal transmission on the Profibus network.

- Electrical isolation components (optocouplers or transformers) to isolate the Profibus network from internal circuitry (important for safety and noise reduction).

- Honeywell sources high-quality electronic components from reliable suppliers that meet their specifications. These might include:

Printed Circuit Board (PCB) Manufacturing:

- PCBs are likely fabricated according to Honeywell's design. These may involve multiple layers with special considerations for signal integrity and noise reduction in a high-speed communication environment. This stage might be outsourced to a specialized PCB manufacturer.

PCB Assembly:

- Automated pick-and-place machines for precise component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Visual inspection and automated electrical testing to verify component placement, functionality, and signal integrity.

- A controlled environment with stringent quality control procedures ensures proper component placement and soldering. This may involve:

Module Assembly:

- Installation of terminal blocks or connectors for Profibus network connection and potentially Ethernet connection.

- Configuration of the module through software tools to define communication parameters and network settings.

- Incorporation of a protective enclosure for environmental protection and potential heat dissipation from electronic components.

- The populated PCB is integrated into the housing of the CC-IP0101. This might involve:

Testing and Quality Control:

- Functional testing to verify communication with Profibus DP devices and data exchange capabilities.

- Compatibility testing to ensure the CC-IP0101 works seamlessly with Honeywell's Experion systems and other Profibus DP devices.

- Performance testing to assess communication speed, data throughput, and latency under various network loads.

- Environmental testing to verify the module's performance within its specified operating temperature, humidity, and vibration ranges.

- Rigorous testing is essential for a communication module like the CC-IP0101, which likely involves:

Documentation and Certification:

- User manuals with clear instructions for safe installation, configuration, and operation.

- Technical specifications detailing communication protocols supported, performance characteristics, and environmental limitations.

- Installation guides for proper integration with Profibus networks and Honeywell's Experion systems.

- Honeywell likely provides comprehensive documentation for the CC-IP0101. This might include:

Packaging and Shipping:

- Once all requirements are met, the CC-IP0101 is labeled according to regulations and securely packaged for shipment. It's then shipped to distributors or industrial automation integrators working on process control applications.

Materials and Manufacturing Technology:

Honeywell likely adheres to high-quality standards and industry best practices for industrial communication modules. Here are some possibilities:

- High-grade electronic components with extended lifespans: Selected for reliability and suitability for harsh industrial environments.

- Traceability of materials: Components might be sourced with lot codes or other tracking mechanisms for quality control purposes.

- Statistical process control (SPC): Techniques might be used to monitor production processes and identify potential issues early on.

- Advanced testing equipment: Specialized equipment for communication protocol testing, network performance analysis, and environmental testing chambers.

- Computer-aided design (CAD) and manufacturing (CAM): Might be used for precise design and production of the CC-IP0101, especially for the PCB layout.

Finding More Specific Information:

Obtaining in-depth details about the exact production process for the CC-IP0101 might be challenging due to its potentially proprietary nature. Here are some suggestions for further exploration:

- Honeywell Website: The Honeywell website, specifically the Industrial Automation section or resources related to the Experion system, might have information about the CC-IP0101's functionalities and compatibility.

- Technical Documentation: If available, search for data sheets, user manuals, or installation guides for the CC-IP0101. These resources might provide details about its features, configuration options, and recommended practices for use.