CC-TDIL01

CC-TAIX01 Honeywell Production Description

Based on the information available online and the understanding that the CC-TAIX01 is a Honeywell analog input module, here's a possible breakdown of its production process:

Possible Production Stages:

Component Sourcing:

- High-precision analog-to-digital converters (ADCs) to convert incoming analog sensor signals from the field into digital data for processing by a controller.

- Signal conditioning components like resistors, capacitors, and operational amplifiers (op-amps) to amplify, filter, and adjust incoming analog signals for optimal conversion by the ADC.

- Microcontroller or programmable logic device (PLD) for handling internal processing tasks (possible depending on the module's functionality).

- Communication interface chips for connecting to a higher-level control system (optional, depending on the module variant).

- Terminal blocks or connectors for secure field wiring of analog input signals.

- Honeywell sources high-quality electronic components from reliable suppliers that meet their specifications. These might include:

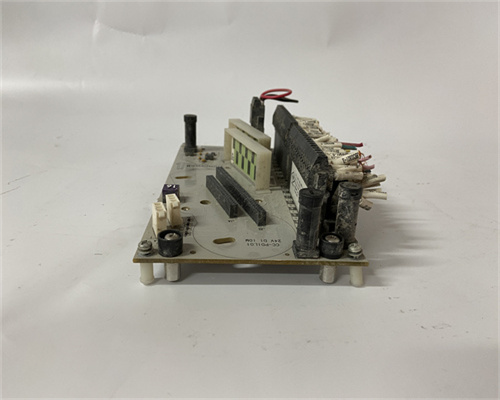

Printed Circuit Board (PCB) Manufacturing:

- PCBs are likely fabricated according to Honeywell's design. These may involve multiple layers with special considerations for analog signal routing and noise reduction. This stage might be outsourced to a specialized PCB manufacturer with experience in high-precision analog circuit boards.

PCB Assembly:

- Automated pick-and-place machines for precise component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Additional hand soldering or rework for sensitive analog components (possible depending on the design).

- Visual inspection and automated electrical testing to verify component placement, functionality, and signal integrity.

- A controlled environment with stringent quality control procedures ensures proper component placement and soldering. This may involve:

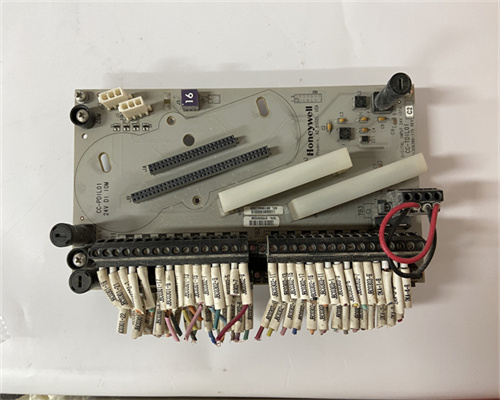

Module Assembly:

- Calibration of internal components (ADCs, op-amps) for accurate analog signal conversion.

- Installation of terminal blocks or connectors for safe and secure field wiring of analog input signals.

- Incorporation of a protective enclosure for environmental protection and potential heat dissipation from electronic components.

- The populated PCB is integrated into the housing of the CC-TAIX01. This might involve:

Testing and Quality Control:

- Functional testing to verify the module operates as intended with various analog input signals. This might involve testing across the specified voltage/current input ranges and accuracy of the digital output data.

- Compatibility testing to ensure the CC-TAIX01 works seamlessly with Honeywell's control systems (e.g., Experion) if a communication interface is present.

- Environmental testing to verify the module's performance within its specified operating temperature, humidity, and vibration ranges.

- Rigorous testing is essential for a product like the CC-TAIX01, which likely involves:

Documentation and Certification:

- User manuals with clear instructions for safe installation, configuration (if applicable), and operation.

- Technical specifications detailing input voltage/current ranges, accuracy, communication protocols (if applicable), and environmental limitations.

- Installation guides for proper wiring of analog sensors and integration with Honeywell's control systems (if applicable).

- Honeywell likely provides comprehensive documentation for the CC-TAIX01. This might include:

Packaging and Shipping:

- Once all requirements are met, the CC-TAIX01 is labeled according to regulations and securely packaged for shipment. It's then shipped to distributors or end users working on industrial automation projects that require analog signal acquisition from sensors.

Materials and Manufacturing Technology:

Honeywell likely adheres to high-quality standards and industry best practices for industrial automation components. Here are some possibilities:

- High-grade electronic components with extended lifespans: Selected for reliability and suitability for harsh industrial environments.

- Traceability of materials: Components might be sourced with lot codes or other tracking mechanisms for quality control purposes.

- Statistical process control (SPC): Techniques might be used to monitor production processes and identify potential issues early on.

- Advanced testing equipment: Specialized equipment for testing analog signal conversion accuracy, calibration tools, and environmental testing chambers.

- Computer-aided design (CAD) and manufacturing (CAM): Might be used for precise design and production of the CC-TAIX01, especially for the PCB layout.

Finding More Specific Information:

Obtaining in-depth details about the exact production process for the CC-TAIX01 might be challenging due to its potentially proprietary nature. Here are some suggestions for further exploration:

- Honeywell Website: The Honeywell website, specifically the Industrial Automation section or resources related to the control system that the CC-TAIX01 is designed for (e.g., Experion), might have information about the module's functionalities and compatibility.