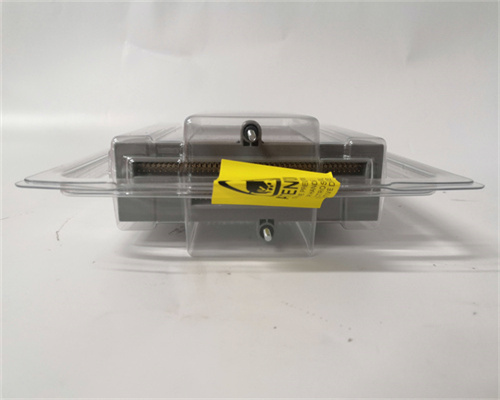

Honeywell SC-UCMX01

Honeywell SC-UCMX01 Production Description

The Honeywell SC-UCMX01 is a Remote Terminal Unit (RTU) within the CONTROLEDGE™ RTU process controller series. Here's a possible breakdown of its production process:

Components:

High-quality electronic components for industrial environments:

- Microcontroller or microprocessor for core processing and control functions.

- Memory chips for storing program code and data.

- Analog-to-digital converters (ADCs) to convert analog sensor signals to digital data (if applicable).

- Digital I/O circuitry for interfacing with digital sensors and actuators.

- Communication interface circuitry (e.g., Ethernet, RS485) for connecting to supervisory control systems (SCADA) and other devices.

- Power supply circuitry to regulate and distribute power throughout the module.

- Galvanic isolation components to isolate input, output, and communication signals for safety and signal integrity (critical in industrial process control).

Housing suitable for industrial environments (e.g., flame-retardant plastic with proper heat dissipation features).

Production Stages:

Component Sourcing:

- Honeywell sources high-quality electronic components from reliable suppliers that meet their performance and reliability standards for industrial applications.

PCB (Printed Circuit Board) Manufacturing:

- The SC-UCMX01 likely utilizes a PCB for its core functionalities. This PCB is likely fabricated according to Honeywell's design by a specialized PCB manufacturer.

PCB Assembly:

- Automated pick-and-place machines for accurate component placement.

- Reflow ovens or wave soldering techniques for secure connections.

- Additional hand soldering or rework for critical components (possible depending on the design).

- Automated and visual inspection to verify component placement and functionality.

- In a controlled environment with stringent quality control procedures, the electronic components are precisely placed and soldered onto the PCB. This might involve:

Programming and Testing:

- Electrical testing to verify signal processing capabilities, I/O channel operation, and communication protocols.

- Performance testing to assess processing speed, communication speed, and response time under various load conditions.

- Functional testing to verify the module's ability to interact with sensors, actuators, and SCADA systems as intended.

- Environmental testing to verify the module's performance within its specified operating temperature, humidity, and vibration ranges.

- The PCB is likely programmed with the necessary firmware to define its communication protocols, control logic, and functionality for process control applications.

- Rigorous testing is performed to ensure proper functionality, including:

Final Assembly and Packaging:

- The completed PCB is placed in its designated housing.

- Any additional components like terminal blocks for user connections are installed.

- The final assembly undergoes a final round of inspection for functionality, safety compliance, and cosmetic defects.

- Secure packaging is used to protect the RTU during transportation and storage.

Documentation:

- User manuals with clear instructions for safe installation, configuration, programming (if applicable), and operation within a process control system.

- Technical specifications detailing communication protocols, supported sensor/actuator types and voltage ranges, environmental limitations, and safety certifications.

- Honeywell likely provides comprehensive documentation for the SC-UCMX01, including:

Additional Notes:

- The specific production process might vary depending on the exact variant of the SC-UCMX01 model.

- Honeywell likely has a robust quality management system in place to ensure the reliability and performance of their industrial process control products.